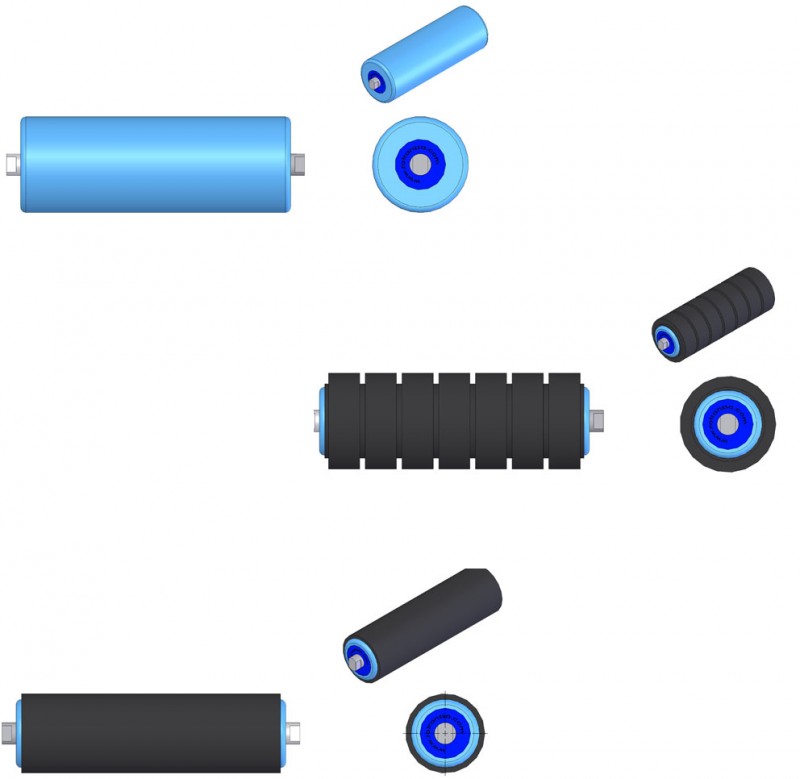

SMOOTH ROLLS

They are used as transport rollers and as return rollers.

Diameter of the most used axes: 12 mm - 60 mm.

With ball bearings

Tube diameters comply with DIN, ISO, FEM and CEMA standards

SHOCK ABSORBER ROLLS

Its application is in the areas of impact loading, transfers, etc., of conveyor belts, or where blows and impacts are received on the belt.

They are manufactured of two types:

With solid rubber rings in combination with the tube diameters

Vulcanized / bonded (hot molded)

Rubbers cover the entire surface of the roller.

COATED ROLLS

Its manufacture is based on the raw rubber coating on the metal roll and autoclave vulcanization. Both the thickness and quality of the rubber (with anti-oil, anti-corrosion, anti-acid, etc. properties) are tailor-made.

They have different applications; They are used for areas of great wear and friction. In places where it is exposed to acidic, oily substances, in areas of high impact, etc.

Conveyor Rollers

Cleaning rollers

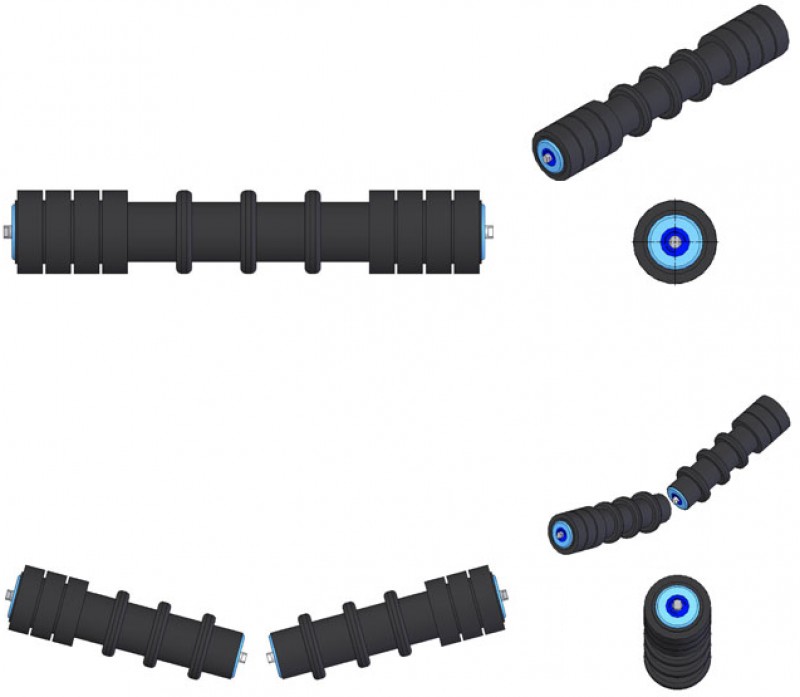

FLAT CLEANING ROLLS

They are rollers that are fundamentally used in the lower part of conveyor belts. Its function is to clean the upper face of the screen (dirty face).

They are formed by smooth metallic rollers and a rubber composition according to the widths of the strips, always with rubber separators between the cleaning discs.

HELICOIDAL CLEANING ROLLS

The helical cleaning rollers are formed by smooth metallic rollers and helicoidal rubber rings, which, if they are for flat return belts, have a tire shape with the helix converging in the center. If these are for a "V" application, the helicoid formed by the rubber rings is only in one direction.

This rolls are manufactured in two types:

With solid rubber rings in combination with the roll diameters

Vulcanized / glued (molded)

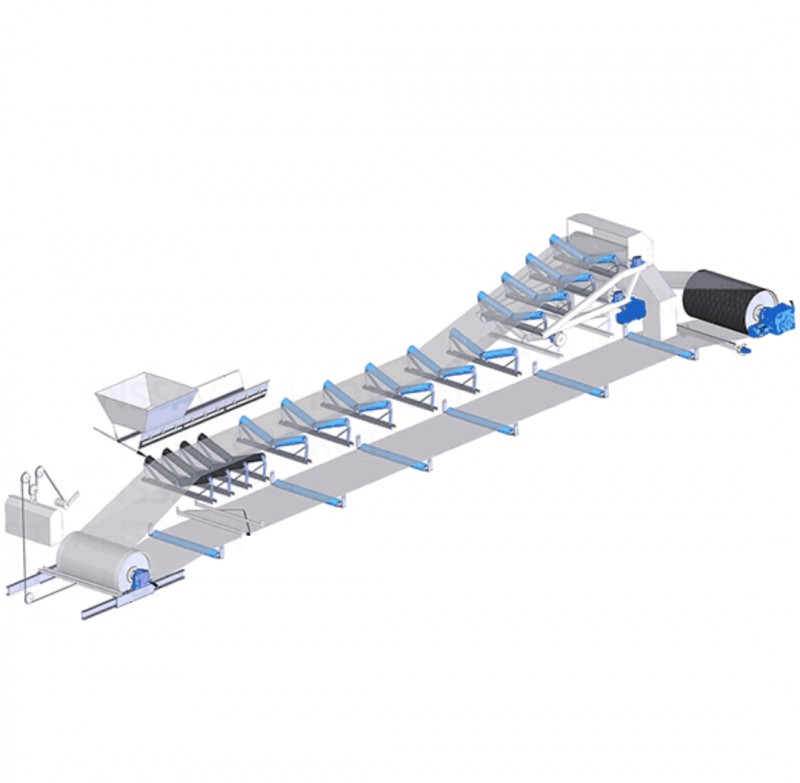

Conveyor Belts

Support rollers

The support rollers form a rail at 20/30 and 45 degrees with or without mooring. The fixing of the stations in the support frame will be done by means of screws or clips.

Centralized auto station

In the top three rollers and as flat bottom. They are used on conveyors exceeding 50 meters in length.

Belt

Belts shall be made according to the requirements of the plant and material to be transported or, at the request of the customer, usually made of textile material and are made up of several layers of polyester and nylon synthetic fiber fabrics with the necessary coatings.

Cleaning scrapers

The primary scraper, located on the discharge head drum, will be blade type. In the case of reversible conveyors, it will be of the rocker type.

The plate scrapers (pre-scraper) are located near the discharge drums.

Tensioning elements

On conveyors whose axle length is less than or equal to 60 m, the return drum will act as a tensioning drum.

In lengths over 60 m, the tensioning system is by counterweight with guides and guards. It consists of three drums and supports, two of inflection and one of counterweight, from which a drawer containing ballast that slides by guides is attached.